Insulated Panels

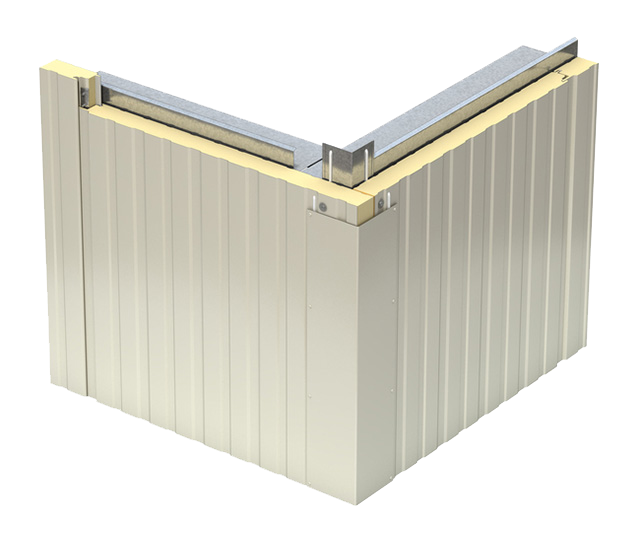

Our insulated panels are a prefabricated modular construction designed for fast and easy field assembly, relocation, and future expansion with the addition of like panels.

Panels are designed to be used in temperature controlled and hygienically safe environments such as food processing facilities, frozen food, cold/frozen warehouses and clean rooms. It is designed both for indoor environments, in reinforced concrete structures and in open areas, in accordance with environmental and climatic conditions.

It is designed both for indoor environments, in reinforced concrete structures and in open areas, in accordance with environmental and climatic conditions.

Specifications

- Width: 1000mm

- Thickness: 80mm, 100mm, 120mm, 150mm

- Colour: Ral9002

- Panel Surface: Corrugated or Flat

- Panel Density: 40 (±2) kg/m3

- Sheet Type: Polyester, PVC

- Sheet Thickness: 0.45mm / 0.50 mm

- Lock Detail: Without lock

Insulated Panels used between -40°C and room temperature.

It can be produced resistant to fire (B1 Chemistry certified)

It provides high performance thermal insulation.

It contains a joint detail that can accommodate hygienically safe sealant that provides excellent thermal performance.

It is hygienically safe, resistant to moisture ingress and minimizes the risk of toxic and bacteria growth.

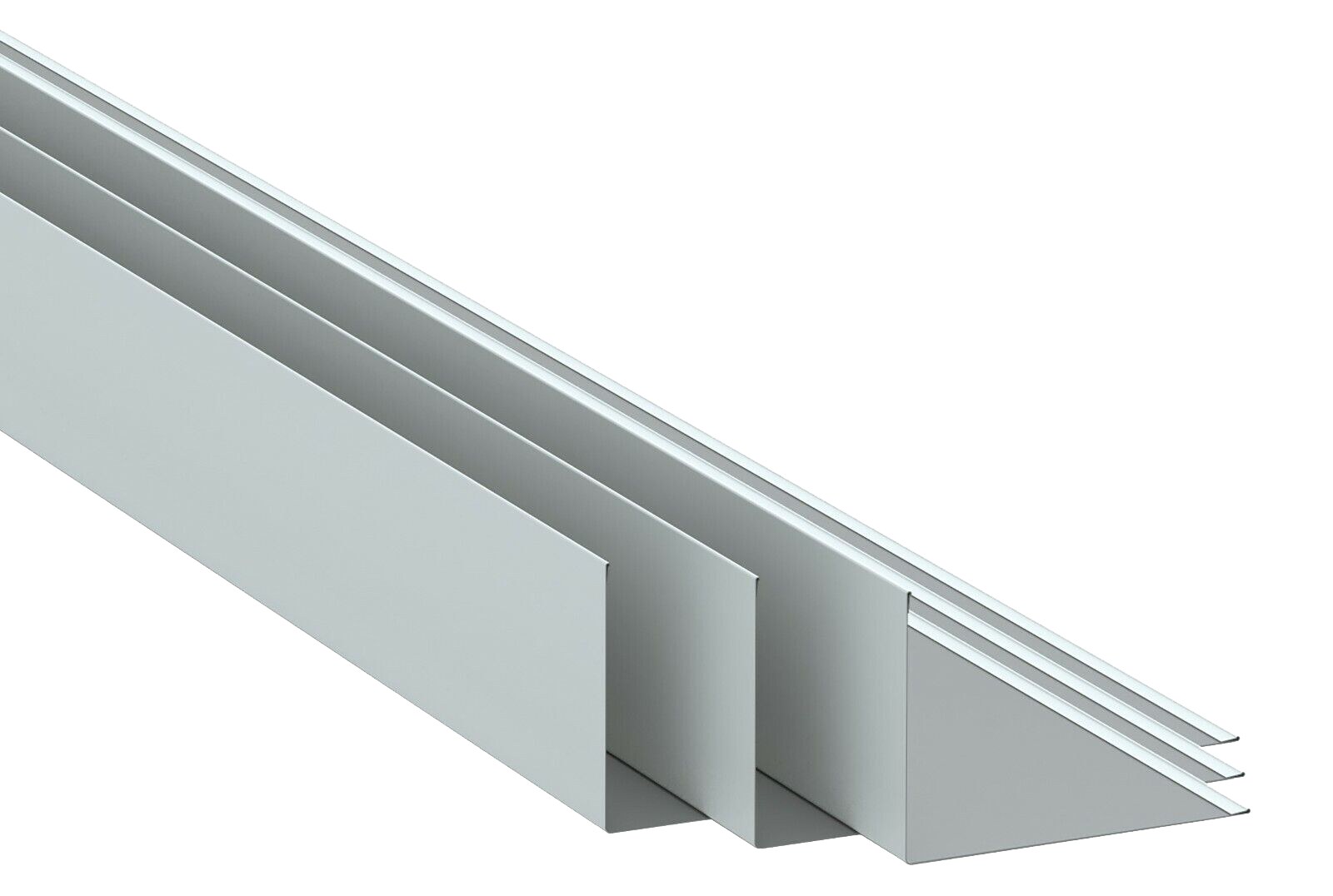

Flashings & Angles

Flashings and angles are essential components in constructing cold rooms or refrigerated spaces. They help create a sealed and insulated environment to maintain the desired temperature. Here are some key aspects related to flashings and angles for cold rooms.

When designing or setting up a cold room, consulting with professionals or experts experienced in refrigeration systems can ensure the proper selection, installation, and maintenance of flashings and angles to meet specific requirements and standards.

They are the profiles used in the assembly of floor, wall and ceiling panels to each other.

Profiles can be PVC or polyester coated galvanized sheets or CrNi according to the panel surface.

Mounting profiles are accessories of various sizes and features developed for adjusting the floor seating arrangement of the panels in cold room installation, eliminating the visual pollution that may occur at the edge and corner joints, providing hygiene and mounting ceiling panels.

Floor Panels

Floor panels in cold rooms play a crucial role in maintaining the desired temperature and ensuring a hygienic and durable surface. Here are key considerations for floor panels in cold rooms:

Our Cold Room Insulation Floor Panels, engineered for optimal thermal efficiency. Featuring a high-density polyurethane core sandwiched between durable steel sheets, these panels offer exceptional insulation, maintaining consistent cold room temperatures. Their robust design withstands heavy use, while the easy-install feature ensures swift setup. Upgrade your cold storage solutions with our Cold Room Insulation Floor Panels.

It’s designed to be suitable for both enclosed environments, such as concrete structures, and open spaces, considering environmental and climatic conditions.

- It can be used within the temperature range of -40°C to room temperature.

- Provides high-performance thermal insulation.

- Includes a joint detail that ensures excellent thermal performance and can accommodate a hygienically safe sealant.

- Ensures hygiene safety, resistance to moisture ingress, and minimizes the risk of toxic mold and bacteria growth.

Offering a bespoke service to suit your needs, Pacific Cooling is committed to supplying the right products with the right assistance and are available to help with any enquiries that will help to improve production and enhance enjoyment for your home or business.